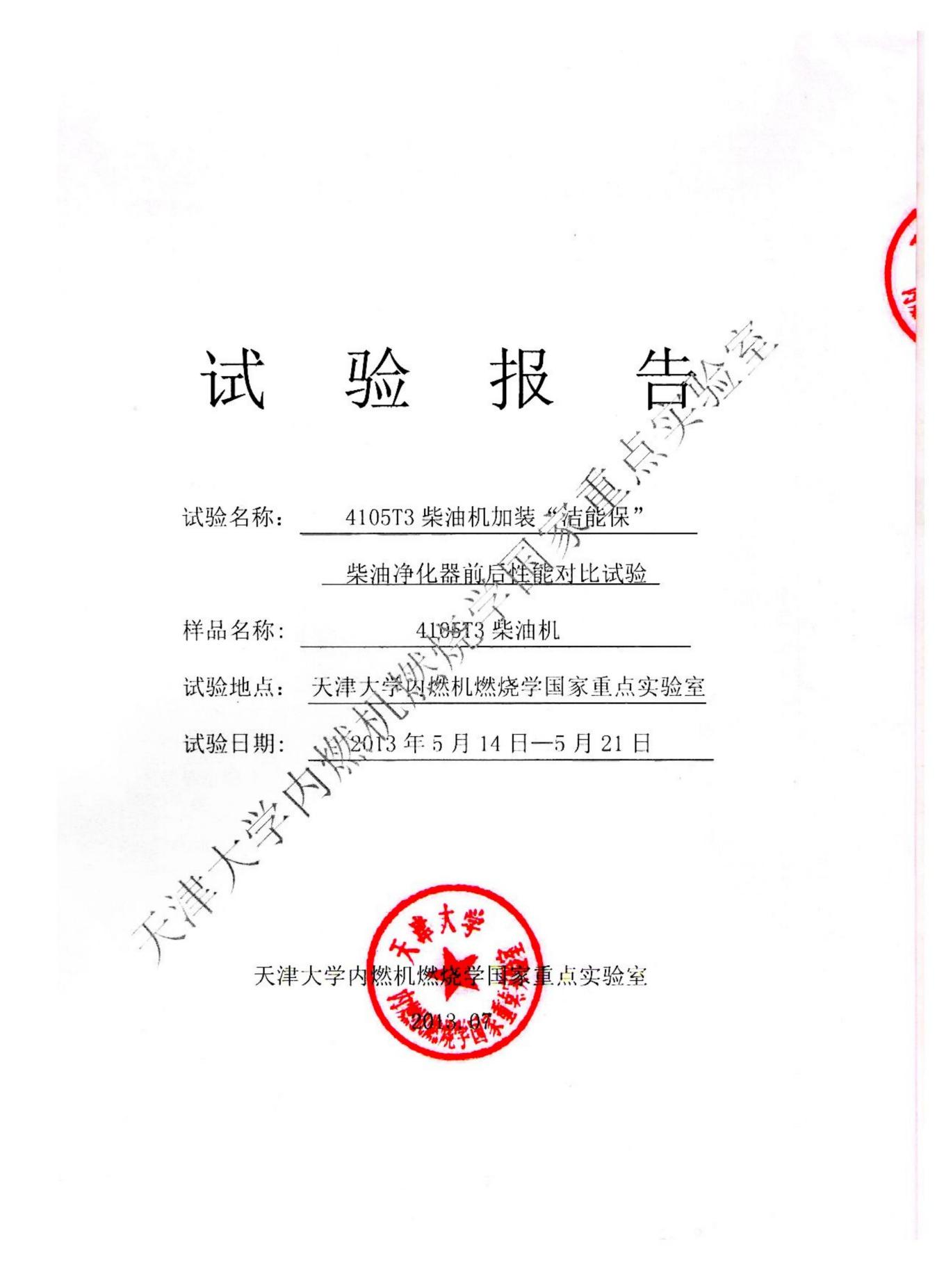

In July 2013, the State Key Laboratory of Combustion Science of Internal Combustion Engine of Tianjin University conducted the ‘Comparison Test of Diesel Engine

Performance before and after 4105T3 Diesel Engine is retrofitted with “Clean Energy” Diesel Purifier’. The test report shows:

The test report shows that after installing ‘Jie Neng Bao’ diesel fuel purifier, the engine runs for 11 minutes and compares with the original engine:

Fuel consumption rate at 1300rpm is reduced by 5.5% on average and 1.14% on average. The maximum reduction of K-value of light absorption coefficient of smoke

is 2.59m-1, the maximum reduction rate is 94.4%; the average reduction rate is 0.9m-1, the average reduction rate is 52.5%.

The maximum reduction of 1600rpm fuel consumption rate is 1.35%, and the average reduction is 0.82%. Smoke light absorption coefficient K value of the maximum

reduction of 1.51m-1, the maximum reduction rate of 50%; average reduction of 0.34m-1, an average reduction rate of 32.7%.

Comparison between the original machine and the one installed with ‘Clean Energy Protection’ running for about 5 hours.

Fuel consumption rate at 1300rpm is reduced by 7.04% at maximum and 2.07% at average.

The oil consumption rate at 1600rpm is reduced by 3.29% on average and 2.16% on average.

Comparison with the original machine after replacing the oil outlet valve:

1300rpm oil consumption rate is reduced by 22.7% maximum and 8.4% average. Smoke light absorption coefficient K value is reduced by a maximum of 8.17m-1,

a maximum reduction rate of 93.7%; an average reduction of 2.4m-1, an average reduction rate of 90.7%, the number of particles concentration is reduced by a

maximum of 84.4%, the mass concentration of particles is reduced by a maximum of 85.7%.

The maximum reduction of 1600rpm fuel consumption rate is 18.9%, and the average reduction is 6.7%. Smoke light absorption coefficient K value is reduced by

a maximum of 7.78m-1, with a maximum reduction rate of 89.7 per cent; an average reduction of 1.87m-1, with an average reduction rate of 79.7 per cent, a

maximum reduction of 84.6 per cent in the quantity concentration of particulate matter, and a maximum reduction of 91.2 per cent in the mass concentration of

particulate matter.