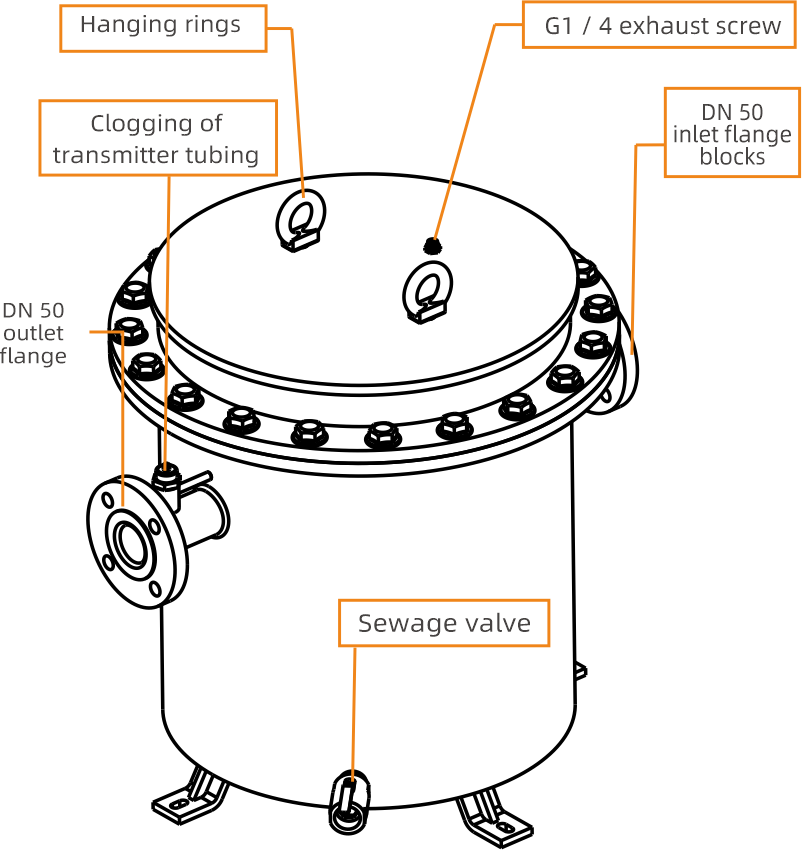

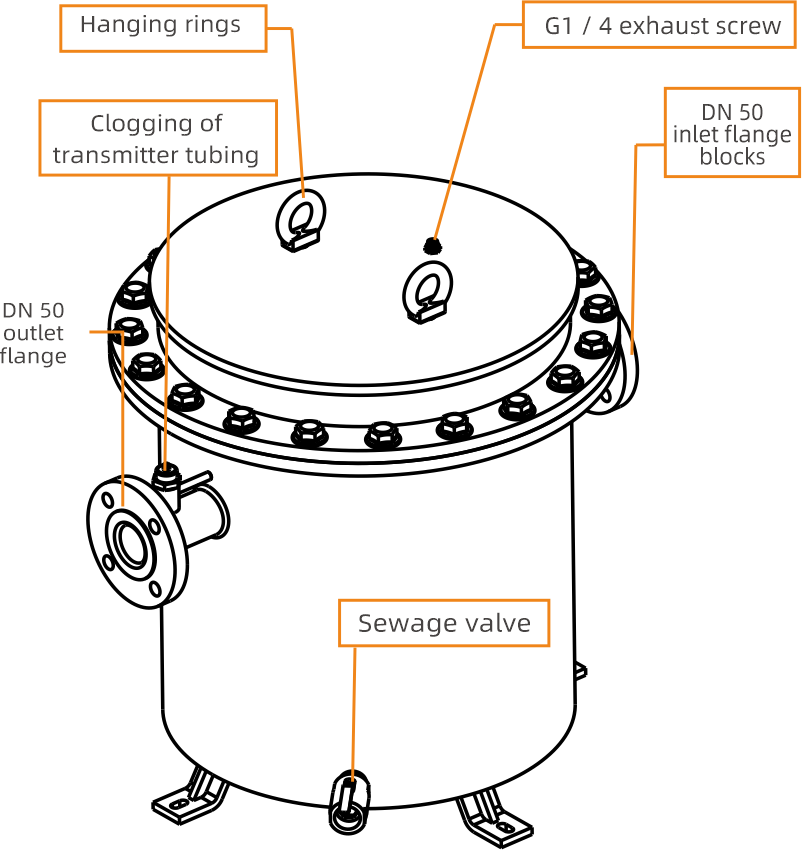

Installation of THY-4113A Diesel Purifier

When using, the product should be connected in series on the oil supply pipeline between the engine and the fuel tank (or the tanker and the oil storage tank).

Note that the in-in (out) oil direction can not be connected backwards. THY-4113A purifier shall add oil pump to provide power for medium circulation. When first

using or replacing the filter element, attention should be paid to drain the internal air.

Operation of water drainage and sewage discharge

THY-4113A diesel purifier has a strong function of oil and water separation. When in continuous use, it should be drained and discharged once every 10 days or so.

That is, open the sewage valve of the diesel purifier, when the water and sewage oil are discharged, and the net oil flows out, close the sewage valve, that is, to

complete the drainage and sewage operation.

Replacement of the filter element

Under the normal use of THY-4113A, replace the differential pressure transmitter alarm or cumulative use for more than 3000 hours with the filter element:

①Close the inlet and outlet oil valves, release the fastening screw of the upper cover and open the upper cover.

② Open the sewage discharge valve and discharge the sewage oil.

③ Take out the old filter element vertically upward.

④ Put in a new filter element.

⑤ Close the sewage discharge valve, cover the top cover (note the sealing ring installation in place), tighten the top cover fastening bolts.

⑥ In the oil pumping mode, the cylinder should be filled with diesel oil, drain the air in the barrel, and open the oil inlet valve, open the oil inlet valve, open the

exhaust screw, tighten the exhaust screw immediately, and open the oil screw valve.

Overall dimension (mm): 740 630 780 (length, width and height)

Import and export oil pipe interface: DN50 flange connection

Flow rate: 0-500L / min

Maximum working pressure: 0.6MPa

Net weight: 185kg

Filter element model and quantity: C1040ADLR x 13 pcs